74 Results

Nos favoris :

COMBINE RASP BARS

Designed to provide long life with optimal performance and unmatched grain quality, CNH Industrial rasp bars keep your combine operating at peak productivity.

Parts That Matter

Rasp bars are crucial components in threshing. You depend on them to help your combine separate grain and chaff. Knowing when to replace them is key to preventing grain loss and grain damage. Typically, you should replace rasp bars when their serrations are worn down to about 3/16", especially for hard-to-thresh crops.

But don’t forget to look for signs of damage, such as cracks, chips and twists. That’s because broken rasp bars can stop you in your tracks, causing irreparable damage to everything from other rasp bars, support brackets and the rotor cage to vanes, grates, extensions and chopper knives.

The potential for costly repairs and downtime is also a good reason to avoid “will-fits” made with inferior designs and materials. They might save you money in the short run, but at what risk? With rasp bars from CNH Industrial — designed, tested and approved by CNH Industrial engineers — you get original equipment quality, plus all new hardware for easy installation.

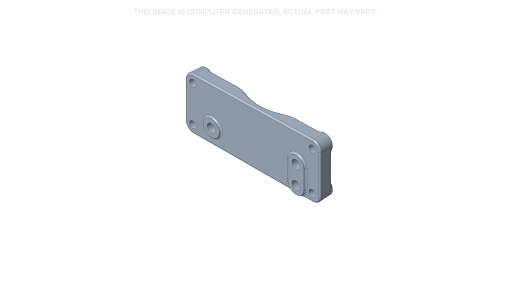

Standard-Duty Rasp Bars

For most crops and conditions, our standard-duty rasp bars are your go-to. They’re made from high-strength nodular iron, quenched and tempered for improved wear resistance and weight-sorted for maximum performance, balance and efficiency. Leading rasp bars are hard-surfaced for even longer wear.

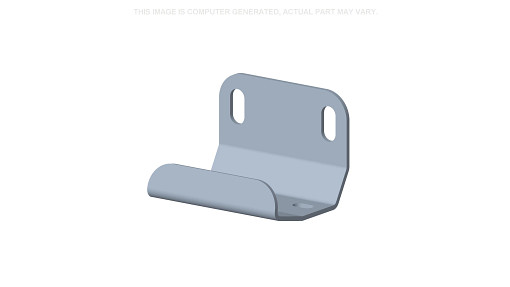

Heavy-Duty Extenda-Wear™ Rasp Bars

Ideal for hard-to-thresh crops, our cast chrome alloy rasp bars feature thicker casting, including an extra 5/16” thickness on the leading edge. The tapered radius in corners prevents cracks, while the reinforced ring around the bolt hole provides added protection. We’ve also changed the angle of the leading edge for improved material flow and resistance to rock damage. For better vane retention, Extenda-Wear™ rasp bars come with larger diameter T-bolts with more head wear surface. Kits are available with spiked bars for aggressive combining of tough or green-stemmed crops.