Variable Rate Technology

Variable rate technology is for those who are further along in their precision farming journey and requires a precision farming-ready display to take advantage of the benefits. Having a conversation with your Case IH dealer should be your first step when considering implementing these technologies into your operation.

We have the variable rate fertilizing, seeding and sprayer rate technologies that are compatible with both Case IH and mixed fleet ecosystems. So whichever one you run, we have the hardware and software to help you maximize your efficiencies day in and day out.

While upgrading your current equipment with variable rate technology can help you achieve greater levels of precision accuracy, you should speak with your Case IH dealer to determine whether it’s a cost-effective option for you and your operation. Investing in new equipment, factory-fit with the latest variable rate technology, is another option to consider.

Deliver seeds and inputs precisely where you want them.

With variable rate technologies—variable rate seeding, variable rate fertilizing and sprayer rate controls—you can increase your accuracy, efficiency and potential yield season after season.

VARIABLE RATE SEEDING

Variable rate seeding allows you to fully maximize your yield potential by distributing your seeds exactly where they need to be to allow for a healthy germination and growing environment. You will need a higher-end precision farming-ready display to help you to realize the benefits of variable rate seeding.

Allow the delivery of seeds in a uniform manner.

Improves accuracy and uniformity of seed placement in furrow by gently pushing seed firmly into the soil.

Meters are used to ensures singulation planting to help mitigate skips and doubles while planting.

Ensures your seeds are being planted at the proper depth at the bottom of the trench so it has an optimal chance of producing a strong and prosperous crop.

Provides a clean furrow for more precise seed delivery.

A system that closes the furrow, allowing the seed to germinate.

A system that provides downforce to ensure a consistent seed placement depth

Precision Planting SpeedTube®

A seed delivery system for planters that helps increase planting speed and improve accuracy and performance of seed placement. (works well with beans, corn, cotton and sugarbeets)

- vSet®, vDrive® and SpeedTube are all required to be installed together for fast and efficient seed placement

- Component of the 10-mph planting solution

- Eliminates seed tube bounce of seeds

- Seeds are released to match ground speed, which reduces furrow tumbling

Precision Planting WaveVision®

Measures seed populations by using high-frequency radio waves to measure mass instead of shape so the seed can’t be confused with dust particles.

- Counts seeds, not dust, for greater planting data accuracy

- To prevent seed tube wear, it’s constructed with tungsten carbide wear tips

- Does not use an optical sensor to ensure the prevention of seed ricochet, which can cause skips/doubles

- In-cab visualization of seed frequency through Case IH Pro 700 or 1200 displays allows operator to easily see seed skips or multiples

Precision Planting SmartFirmer®

A seed firmer sensor that measures the amount of moisture, organic matter and temperature available to the seed, so the operator can adjust to a correct depth and assures you have a consistent crop stand.

Precision Planting vSet®

This meter singulates seeds accurately without any adjustments, resulting in precise and consistent seed placement throughout the field.

- Simple to use; easy to maintain

- Requires no adjustments

- Accurate and consistent regardless of seed size or shape; delivers 99% accuracy without adjustment in corn and beans

- Approved for: beans, corn, cotton, peanuts, sugarbeets and sunflowers

Precision Planting vDrive®

Replaces the mechanical drive system, which simplifies your planter. The vDrive motor mounts to each vSet meter and makes the row a single row planter where each row is controlled individually.

- Boundary control eliminates over-planting

- Allows for accurate seed population

- Ensures precise per-row seed metering

- Curve-compensated spacing delivers optimal seed singulation

- Each individual row can change rate independently, giving you correct population during variable rate seeding

Precision Planting mSet®

Multi-hybrid planting system that allows you to plant two hybrids using a divided hopper with one vSet meter.

- Works on its own or with SpeedTube® for high-speed multi-hybrid planting

Precision Planting SmartDepth™

Allows you to quickly and easily adjust the depth of your furrow.

- As conditions change, adjust furrow depth from the comfort of the cab

- Saves time and effort

- Instills confidence that each row is set right where you need it to be

Precision Planting Reveal™

Precisely controls the cleaning tines for a clean seeding environment for emergence to occur.

- Frame-mounted to lessen the stress on the row unit

- Employs an internal gauge wheel and treader wheels

Precision Planting CleanSweep®

Removes debris from the soil surface to prepare the seedbed to be formed by the opening disks and furrow formers.

- Adjust row cleaners from the comfort of the cab, saving time and increasing productivity

- Reduces moisture wicking residue from the furrow

- In-cab adjustments prevent the soil from being plowed out of the way

Precision Planting FurrowForce®

A two-stage closing system that adapts to your planting conditions to provide a balanced soil-water-air environment.

- Notched wheels work close to the seed furrow from the bottom up, eliminating air pockets

- Stitch wheels carry weight on the furrow to firmly smooth the soil over the seed, retaining moisture

- Can automatically adjust row-by-row force applied to the unit

Precision Planting DeltaForce®

Provides consistent downforce to place seeds at their optimal depth in changing field conditions.

- Automatically adjusts downforce during changing field conditions for desired seed depth

- Consistent seed depth row-to-row and field-to-field

- Real-time adjustment of weight on gauge wheels

Variable Rate Fertilizer & Spray Rate Technology

Similar to variable rate seeding, this aspect of precision farming requires you have a higher-end, precision farming-ready display to take advantage of its benefits. If your goal is precise fertilizer placement, Precision Planting offers a variety of solutions. If crop input application is a priority, consider the Raven product options as well.

These options will help you work efficiently and effectively in the field.

Easily adjust applied rates on the go.

Solutions that help operators work more efficiently while fertilizing and spraying.

Precision Planting Conceal®

- Planter fertility attachment

- Neatly attached into the row unit

- Places nutrition in the soil 3 inches away from the seed

Precision Planting FurrowJet®

- Firms the seed in the trench

- Places bands of fertilizer on and near the seed

- Provides the nutrients early roots need

- Ensures that plants never go hungry

Precision Planting vApplyHD®

- Allows you to apply the correct rate of liquid fertilizer to every plant in your field

- Plants never go hungry

- Helps maximize fertilizer ROI

Precision Planting FlowSense™

- Measures the rate of fertilizer you’re applying on each planter row or sidedress bar

- Informs you of any row-to-row variability

- Inspires confidence in your application rate

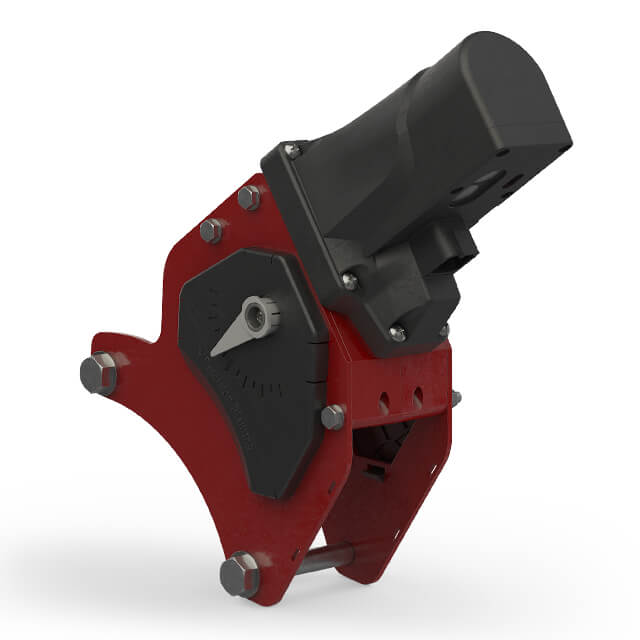

Precision Planting Pump Stack

- Easily pairs up your application technology with fertility rates

- Designed to work with Precision Planting’s Fertility System or other rate controllers

- Allows you to design a liquid fertility system

Precision Planting RateController™

Precision Planting’s RateController makes it easy for you to adjust applied rates and compensates for speed changes on the go.

Raven VSN®

- Non-contact camera-based unit that provides machine guidance through emerged to full-canopy crops

- Easy to use and allows operator to cover more acres due to increased speed and more efficient field planning

- Highly precise, instantaneous crop row information is fed into the auto steering component so it can adapt to row variances in real time

- Uses controlled traffic patterns to actual planted rows minimizing crop damage for reduced respraying and weed infestation

- Allows operators to drive damage-free speeds up to 20 mph

- Helps you cover more acres per day, maximizing yield and ROI

Raven Hawkeye® II Nozzle Control

- Efficient spray control system with consistent flow control, accuracy and field durability

- Individual on/off nozzle control valves are accurate and self-adjust to corners, contours and headlands to avoid over- and under-spraying

- Work faster and save on input costs

- Make fewer tip changes

- Helps to improve your coverage quality and minimize input costs

Raven Rate Control Module (RCM)

- Rate control module that lets you control up to 5 liquid and dry products per controller

- Easy to calibrate, tune and troubleshoot with diagnostic tests and readings

- Supports more than 200 different application systems, including air seeders, planters, sprayers, spreaders, toolbars and sidedress applicators

- Stores up to 8 transferable individual profiles that can be used across machines

- Intuitive interface via ISOBUS virtual terminals for operators of all skill levels

Raven AccuFlow™

- An anhydrous ammonia (NH3) distribution system that converts gas to liquid, keeping it cold and fluid during application

- Fast cooling and high capacity

- Application rates up to 80 gallons per minute allow you to cover more acres per day

- Replaces dual cooler systems (when paired with Raven control system) to deliver more accuracy, less product waste, lower input costs and faster application speeds with less refills and higher yields

Raven AccuFlow™ HP

Delivers the same benefits as the Raven AccuFlow™, plus the following two features:

- Two-Stage Valve Control System: When flow demand exceeds a fully opened valve, the HP pump engages to reach desired rate

- Dynamic Valve Control: Commanded to react at a slower speed for lower rates and faster speed at faster rates

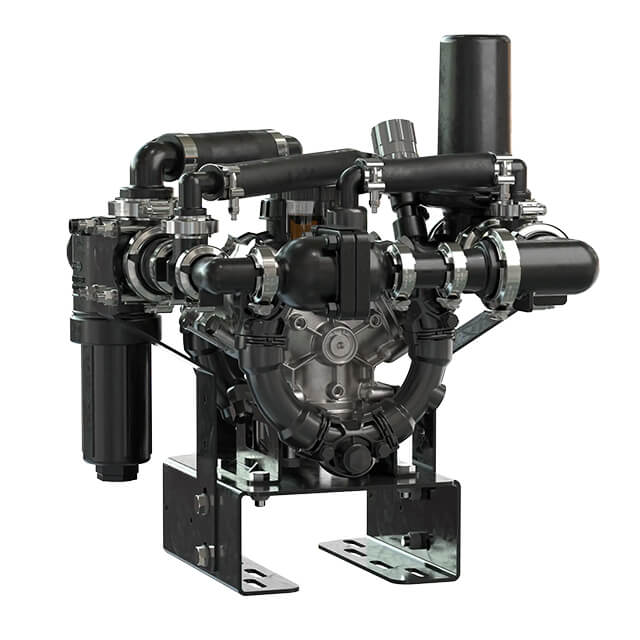

Raven Sidekick Pro™ Direct Injection

- Direct injection system executes chemical application with precision, savings and safety

- No tank mixing required

- Automatically adds the correct amount of product directly into the stream of your sprayer booms

- Prevents cross-contamination and reduces waste from unused product

- Automatic calibration feature gets you ready to go in minutes

- Its Rinse Assist feature automatically flushes the pump quickly and thoroughly

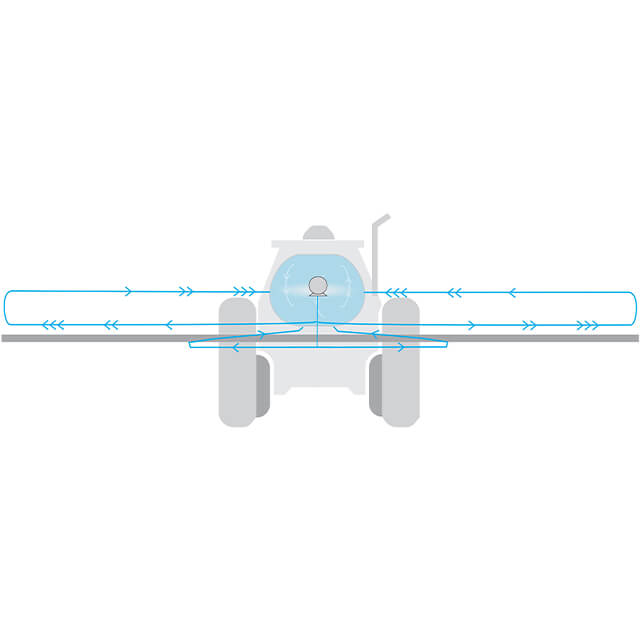

Raven Boom Recirculation™

- Uses add-on hardware to aid in efficient clean out of the boom and plumbing system

- Helps reduce product settling and eliminates waste

- Increases your uptime and helps you achieve uniform product application

- Prevents chemical dumping, protecting the environment

- Automatic calibration feature gets you ready to go in minutes

- Boom recirculation is activated with a software upgrade through AIM Command Flex™ or AIM Command Flex II

Case IH AIM Command Flex II

- Works to maintain your ideal chemical application rate, pressure and accuracy, regardless of speed or terrain

- Optimizes application rates and droplet sizes for consistent application

- Sprays at faster speeds or applies more product as needed with 17% higher flow rates

- Compensates for different speeds across the boom to ensure correct application rates during turns